Hammer mills are vital components in modern manufacturing and play an essential role in a wide range of industries. These powerful devices break down materials into smaller, more manageable sizes, processing grains into animal feed, turning waste wood into mulch, and breaking down scrap materials for reuse.

Ultimately, these tools are at the heart of innovation and productivity. In this article, we’ll explore the top uses for hammer mills and how they continue to drive advancements in manufacturing.

Glass Crushing and Recycling

Hammer mills play a pivotal role in glass crushing and recycling, transforming waste glass into usable materials with remarkable efficiency. These machines are essential for breaking down glass into smaller, uniform particles, which manufacturers can then repurpose for a variety of applications, including the production of glass containers, insulation materials, and decorative aggregates.

For example, waste glass from industries or households can be crushed and refined using a hammer mill to create cullet, a key component in new glass manufacturing. A hammer mill’s ability to handle different types of glass, whether it’s plate glass, bottles, or decommissioned solar glass, showcases its versatility and importance in modern recycling processes.

Plastics Processing for Reuse

Processing plastic for reuse is another critical application of hammer mills in modern manufacturing processes, particularly for molded products. These machines can also break down plastic materials into fine granules, ensuring a consistent size and texture that’s ideal for molding and extrusion. This consistency is essential in creating high-quality plastic products, such as packaging, containers, automotive components, and various industrial parts.

By ensuring uniformity in the raw material, hammer mills streamline manufacturing workflows, reduce production defects, and enhance overall efficiency. Furthermore, the ability to pulverize recycled plastics supports sustainable practices by enabling the reuse of materials, minimizing waste, and reducing the demand for virgin plastic resources.

Recovery of Precious Materials

These robust machines are capable of breaking down complex materials, such as gold ore, catalytic converters, and electronics, into smaller, manageable particles. This process facilitates the efficient extraction of valuable metals like gold, platinum, and palladium, which are essential for manufacturing high-tech components and luxury goods.

Hammer mills enable the effective recovery of rare and precious resources, streamlining production workflows while promoting sustainability. Their use not only reduces dependency on virgin resource extraction but also contributes to minimizing waste, making them key in the pursuit of sustainable material sourcing in modern manufacturing.

Production of Biofuel Feedstock

Surprisingly, hammer mills are also critical for the production of biofuel because they process raw feedstock materials such as corn stalks, woodchips, and switchgrass. These machines efficiently grind the feedstock into particles of optimal size, which are then used in the production of bioethanol or biodiesel.

Through ensuring uniform particle sizes, hammer mills enhance the efficiency of biofuel production processes, leading to a higher yield of renewable energy. This capability is especially important as the global demand for green and sustainable fuel sources continues to rise.

Animal Bedding and Mulch Production

Agriculturalists rely on hammer mills to produce animal bedding and mulch by efficiently converting woodchips, straw, and other organic materials into appropriately sized particles. This process ensures that bedding materials are soft, absorbent, and comfortable for livestock while maintaining hygiene in animal care environments.

In mulch production, hammer mills allow for precise sizing, creating an ideal texture that promotes aeration and moisture retention in soil, enhancing plant health. By delivering consistent results, hammer mills support both farming and gardening industries, transforming raw organic matter into valuable products that foster sustainable agricultural and landscaping practices.

Food Processing and Spice Grinding

To efficiently grind spices, sugar, grains, and other food materials into specific textures, you need hammer mills to ensure consistency and quality across batches. This precision is essential for creating products like powdered seasonings, sweeteners, and finely milled flours, which are vital in both home cooking and large-scale food manufacturing.

In optimizing the utilization of raw materials, hammer mills not only improve production efficiency but also minimize waste, aligning with sustainable practices in the food industry. Their versatility and reliability make them indispensable tools for meeting the stringent standards of modern food production.

Grain Milling for Food and Agriculture

One of the top uses for hammer mills is in the grain milling processes, where these machines transform raw grains like corn, wheat, and barley into versatile products such as flour, meal, and components for animal feed. With high-speed hammers that crush and grind grains into fine, uniform particles, these machines ensure the consistency required for both food production and agricultural applications.

For food processing, the resulting fine particles contribute to the creation of high-quality products with reliable textures and flavors. Meanwhile, in animal agriculture, hammer mills help produce feed formulations that promote efficient digestion and optimal nutrient absorption, which, in turn, enhance livestock growth and performance.

Construction Material Production

One of the primary uses for hammer mills is pulverizing concrete, asphalt, bricks, and tiles to produce high-quality aggregates. These aggregates are essential for constructing durable roadways and sturdy building foundations, ensuring stability and long-term performance. Hammer mills also excel in processing gypsum, a key material for producing drywall and cement.

In reducing gypsum into fine particles, the equipment facilitates the creation of consistent and reliable raw materials needed for large-scale construction projects. Additionally, hammer mills assist in converting demolished materials into reusable components, contributing to sustainable practices in the construction industry.

Wood Processing

You can’t grind wood chips, shavings, and sawdust into smaller, uniform particles without hammer mills, all of which are essential in the production of high-quality wood pellets. These pellets are a popular choice for renewable energy sources, as they are compact, efficient, and sustainable.

Another key application is preparing raw wood for pulp and paper manufacturing. They efficiently break down wood into fibers, a crucial step for ensuring quality and consistency in paper and related products. Furthermore, they are indispensable in forestry industries, facilitating the creation of value-added wood products or bioenergy materials that contribute to sustainable practices.

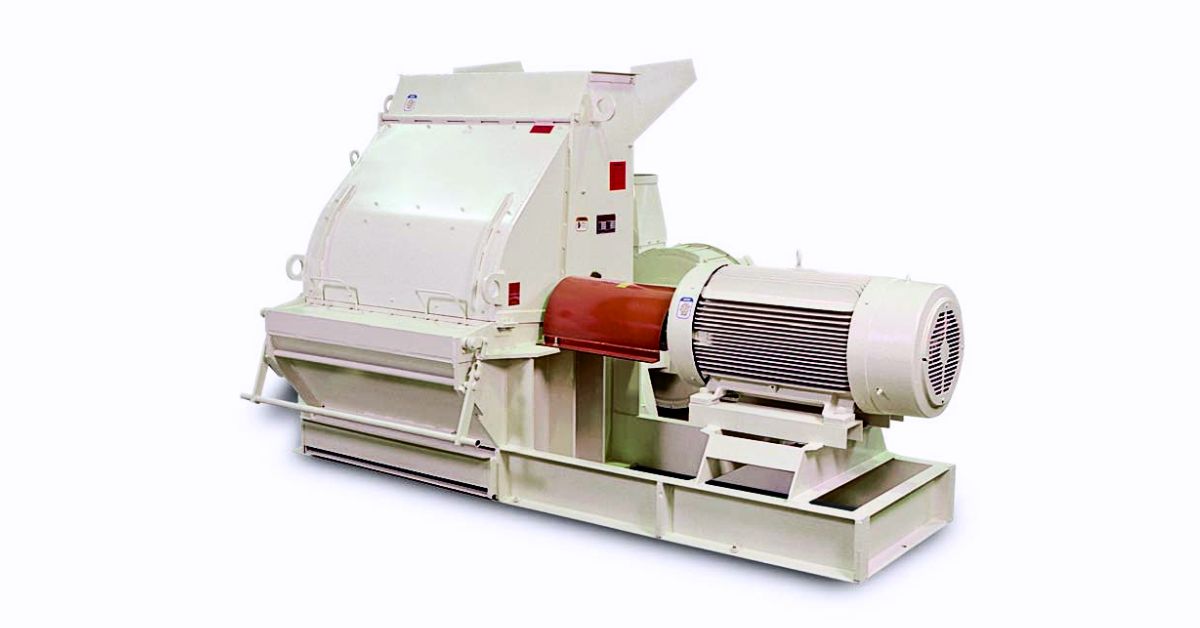

As technological advancements continue to move forward, the role of hammer mills will only expand, further enhancing their impact on modern processes. Why wait to help your business thrive? If you’re ready to harness the full potential of these machines, our collection of industrial hammer mills has something for everybody.

From dual-stage to low and high production models, our hammer mills offer high-quality performance, durability, and efficiency for all your processing needs. With their ability to process a wide range of materials at various sizes, they provide businesses across industries with the flexibility and versatility necessary for success in today’s competitive market.