Size reduction equipment comes in a wide variety of shapes and sizes: vertical or horizontal hammer mills, jaw crushers, roller mills and ram-fed grinders, just to name a few. For the most part, the size and shape of the mill/grinder/crusher plays a key role in the functionality of the machine, and for the applications it is best suited for. Nowhere is this truer than with the Full Circle Screen Hammer Mill.

Size reduction equipment comes in a wide variety of shapes and sizes: vertical or horizontal hammer mills, jaw crushers, roller mills and ram-fed grinders, just to name a few. For the most part, the size and shape of the mill/grinder/crusher plays a key role in the functionality of the machine, and for the applications it is best suited for. Nowhere is this truer than with the Full Circle Screen Hammer Mill.

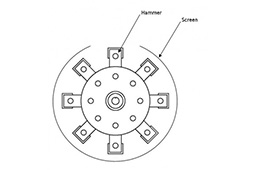

A Peek Inside…

The full circle screen hammer mill gets its name from the 300 degree screen coverage of the rotor, while all other styles of hammer mills typically have closer to 180 degree coverage of the rotor.

Common Applications:

Size Reduction 101:

Size Reduction 101:

When material enters the grinding chamber, it is repeatedly struck by hammers that flail out as the shaft spins. A combination of these hammer blows, particle on particle impact, and impact with the walls of the grinding chamber all work together to break the material down. The material remains in the grinding chamber until it is reduced to a size that will pass through the screen.

The larger the screen area, the greater the opportunity for the material to evacuate the mill. As a result…

Additional Considerations

Once you have decided that the full circle screen hammer mill is best for your material, determining the following criteria will ensure so that the mill is configured to meet your production goals: Material being processed

-Material characteristics such as: friability, flowability, moisture content, and infeed size

-Desired finished particle size – Sawdust, granules, coarse or fine powder?

-Desired production rate – 10 lbs/hr, 10 tph, etc.

- With this information, the following can then be determined:

-Hammer mill size – Rotor diameter and internal mill width.

-Hammer size and style – Number of hammers, size, style and metallurgy.

-Screens – Style and thickness of screen, and size of openings.

-Choice of proper RPM

It’s Optional

Finally, once the the mill is configured, the last determination is whether or not any optional peripheral equipment is needed.

For this, the following questions must be answered:

-How will the material be fed into the mill? By hand, auger, or belt conveyor?

-How will the material be taken from the mill? Gravity, air assist, or full air evacuation?

Is dust a concern?

-Answers to these questions will help to determine the best types of optional equipment such as belt conveyors, augers, rotary feeders, and dust collection, as well as the most efficient design of the infeed and discharge chutes.