Solutions for E-scrap Recycling, Material Recovery & Data Destruction

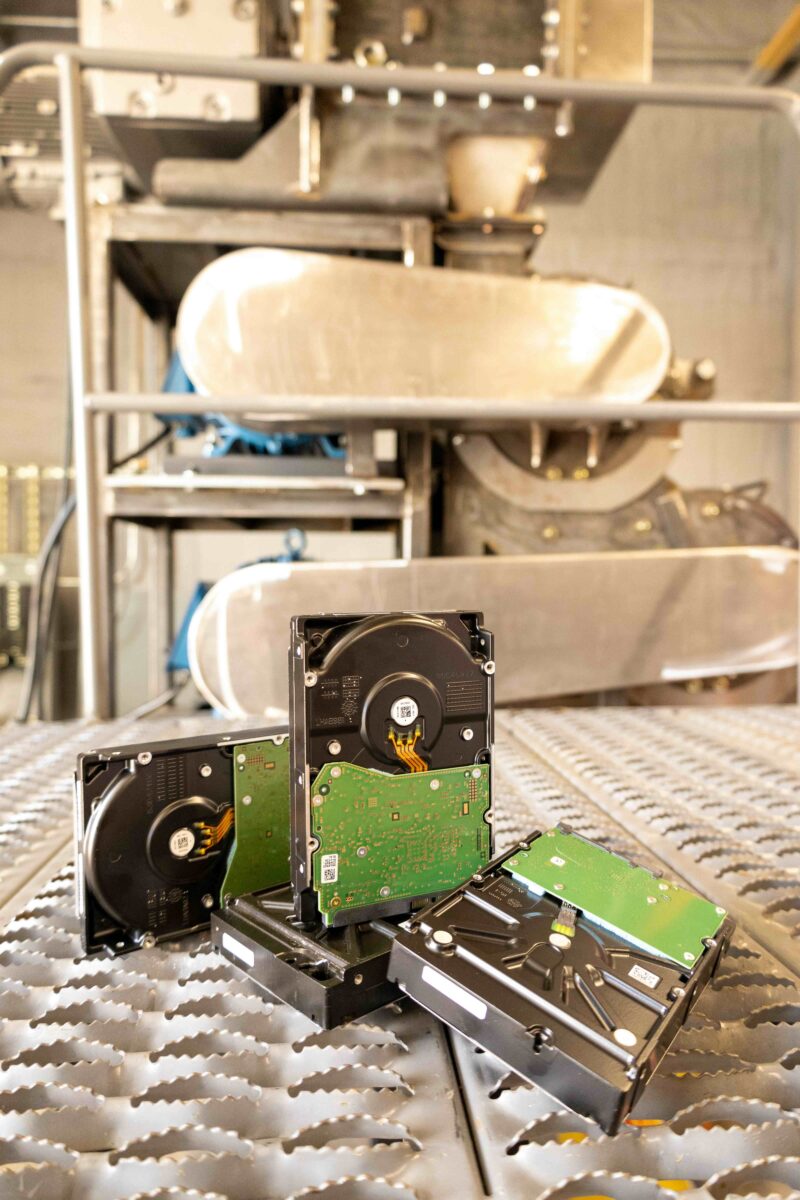

With nearly a century of expertise in the design and manufacturing of size reduction equipment, Schutte Hammermill offers practical equipment solutions for dealing with e-scrap. Whether you’re looking for complete data destruction, processing for material recovery, or just recycling outdated technology, our solutions will effectively process circuit boards, HDDs, SSDs, cell phones, and other e-waste.

Solutions for E-scrap Recycling

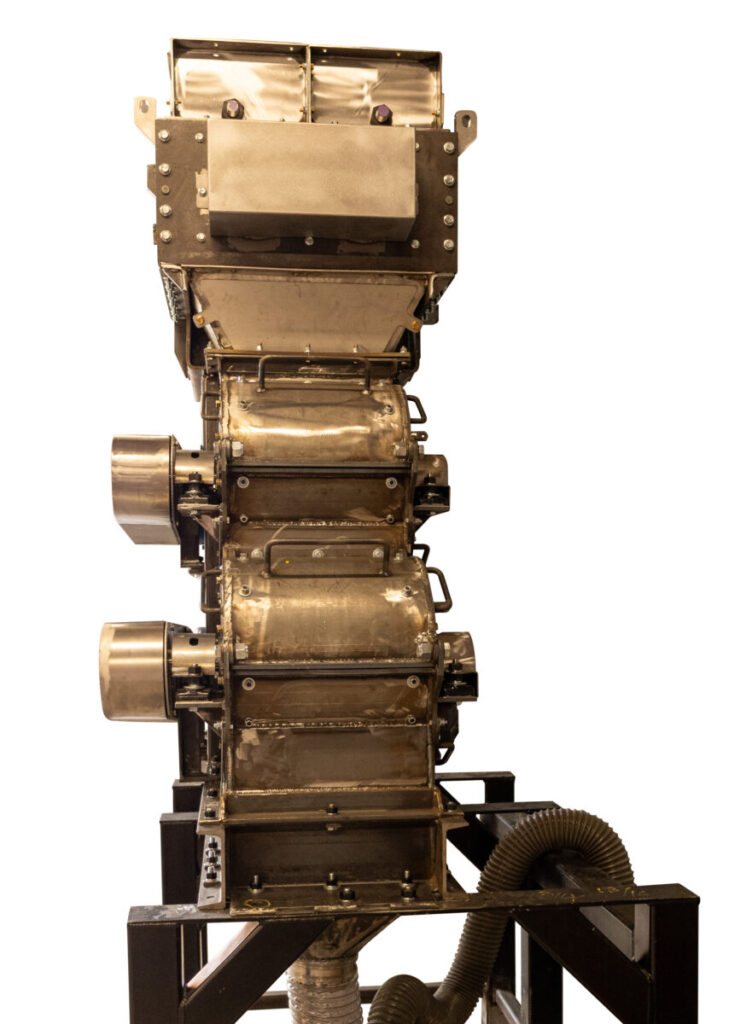

DataKiller Pro

One Pass Data and Electronics Disintegrator

The DataKiller Pro features a unique dual shaft rip shredder integrated with a dual stage hammer mill. This unique design is ideal for super-fine electronic scrap grinding, under 2MM, at very high production rates and at previously unheard of volume reduction ratios. As a result, a sub-2mm grind is achieved in one pass through the DataKiller Pro. The DataKiller hammer mill completely scours electronic media of data while simultaneously liberating the majority of components for easy separation and recycling. With an industry leading ability to process HDDs at a rate of one per second, the DataKiller can also process SSDs, cell phones, printed circuit boards, semiconductors, CDs and more – all without any system reconfiguration.

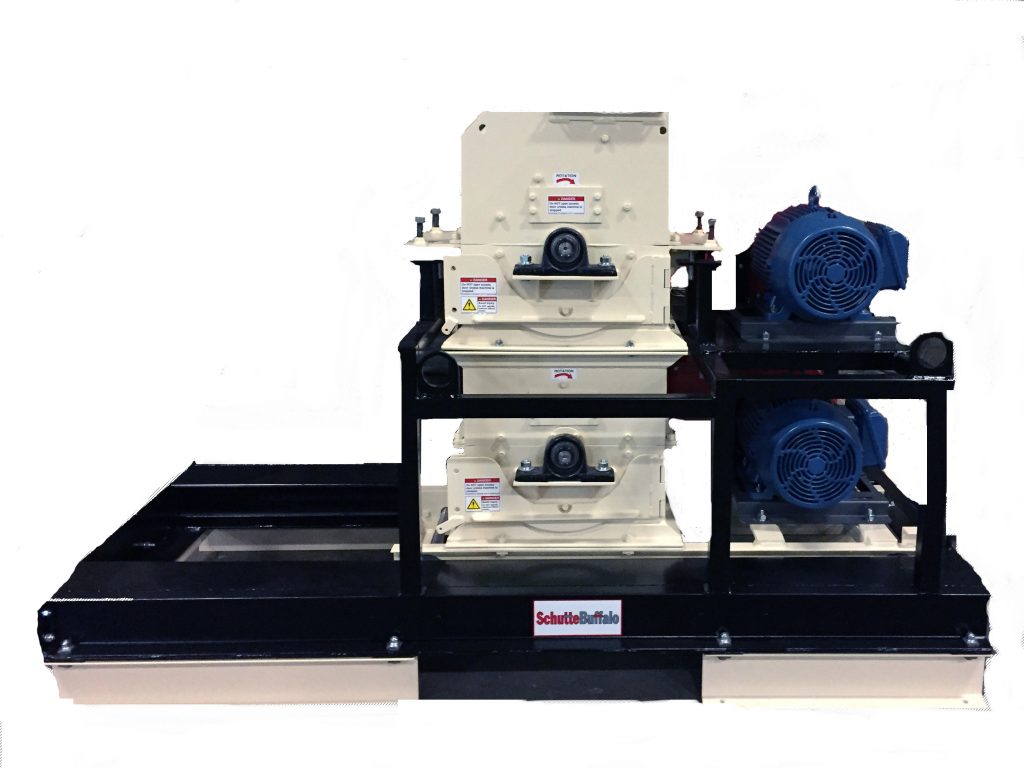

RAS Series

Volume Reduction Made Easy

The RAS Series Dual Stage Hammer Mill features two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine consistency, and grinding free flowing material to an ultra fine finished particle size. The energy resulting from the dual revolving rotors produces a suspension zone that provides additional size reduction. As a result, a finer grind is achieved in one pass through the dual stage mill, than can be achieved in multiple passes through a single hammer mill.

RA Series

Unique design for finer grind

The RA Series Dual Stage Hammer Mill features two gravity discharge industrial hammer mills, stacked one over the other. This unique design is ideal for two distinct processing goals: reducing large, bulky materials to a fine consistency, and grinding free flowing material to a ultra fine finished particle size. The energy resulting from the dual revolving rotors produces a suspension zone that provides additional size reduction. As a result, a finer grind is achieved in one pass through the dual stage mill, than can be achieved in multiple passes through a single hammer mill.

WA Series

Heavy duty mill for abrasive materials

Conventional top feed, bottom discharge hammer mill for processing abrasive and/or difficult to process materials. The heavy duty WA Series is a gravity discharge hammer mill that features components designed for processing hard and highly abrasive materials. A variety of specialty components and materials are available for custom configuration to a particular application.

Ensure Data Security and Maximize Material Recovery from E-Scrap

Data destruction isn’t an afterthought—it’s the foundation of a secure, future-ready data center. Learn how to build destruction into your design from day one.

Let’s Connect!

Contact us for more information or a custom quote! Use the form to the right and one of our team members will reach out shortly.