Content missing

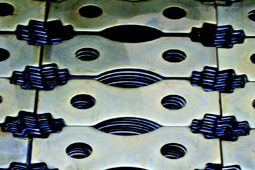

Hammers

Hammermill Replacement Hammers

When you’re ready to replace the hammers in your hammermill, quality and durability are crucial for maintaining optimal performance. Our hammermill replacement hammers will meet the toughest demands of size reduction processes, withstanding repeated impacts and prolonged usage without compromising performance.

Available in various configurations and alloys, our replacement hammers cater to diverse applications, from wood grinding to agricultural processing and beyond. Whether you need high-wear resistance for abrasive materials or specific alloy properties for precision processing, our range of hammermill replacement parts ensures you’ll find the perfect fit for your equipment and requirements.

Each hammer in the collection is precision crafted to provide superior longevity, helping you reduce downtime and lower maintenance costs. With the parts’ straightforward installation, you can quickly and easily replace your hammers, keeping operations running smoothly.

Depending on the application, hammers have either two or four wearing edges to provide maximum wear life.

Hammers should be rotated when the cutting edge is well rounded and the machine is not running at top performance.

Hammers should always be replaced in factory balanced sets.

When to Rotate or Replace:

- Rotate hammers when leading edge becomes rounded.

- Replace hammers when all cutting edges are rounded.