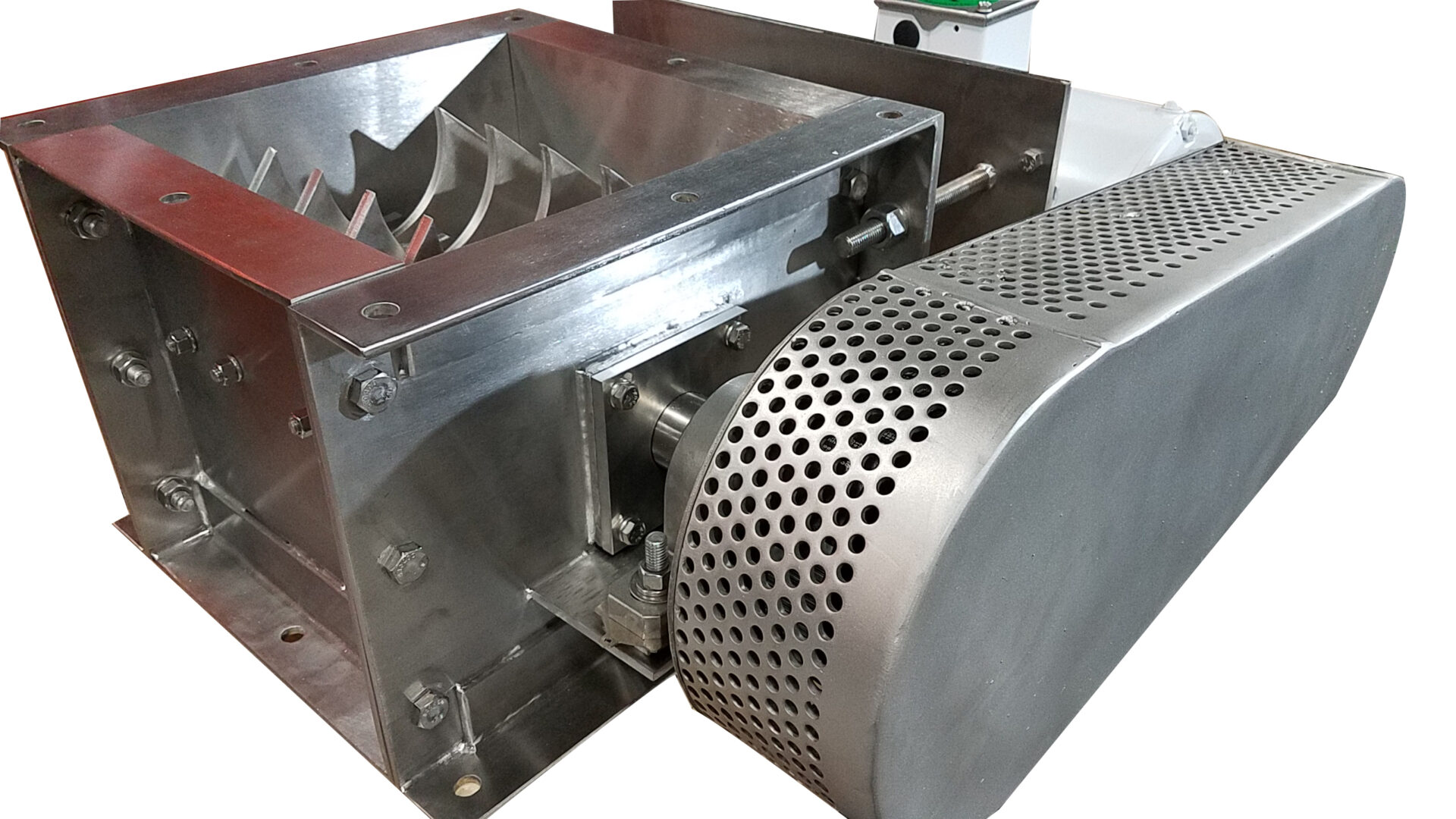

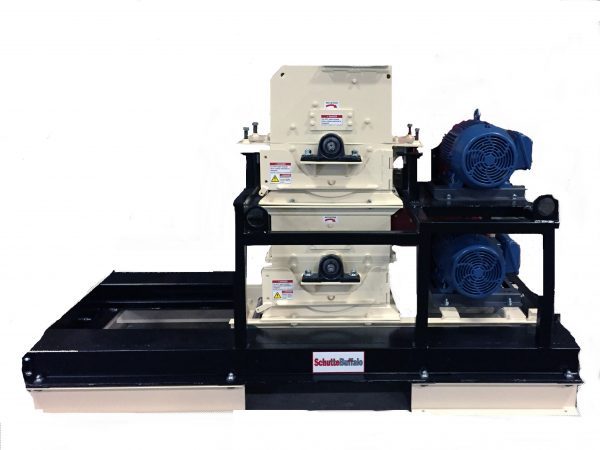

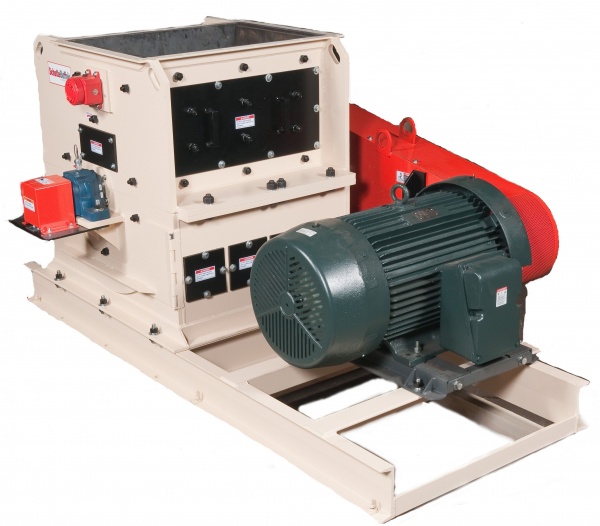

Schutte Hammermill excels in providing tailored solutions for cement processing, offering specialized equipment designed to optimize efficiency and productivity in the cement industry. Our hammer mills are integral in the size reduction process, playing a key role in pulverizing raw materials to achieve the desired particle sizes for cement production. for both in-line or stand-alone applications. Whether your goal is to de-lump cement powder or the reduction of rebar free concrete for recycling or disposal, our mills can produce the exact required finished size. Mobile units and turnkey systems are available, designed for high-productivity and minimal downtime. What sets Schutte Hammermill apart is our commitment to customization, allowing for the adaptation of machinery to specific material characteristics and processing requirements. This ensures that our solutions align seamlessly with the diverse needs of cement processing plants. With a focus on durability and reliability, Schutte Hammermill's equipment is constructed to withstand the harsh conditions of cement manufacturing environments, contributing to prolonged operational life and minimized downtime. Schutte Hammermill's expertise in providing comprehensive support, including readily available spare parts, further solidifies Schutte Hammermill as a trusted partner in delivering efficient and robust solutions for the cement industry.

Equipment for Cement

Reference Materials

Processed Materials

Cement

Concrete