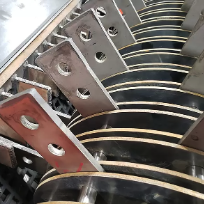

Machines that reduce the size of a material also erode the grinding elements. In general, the more abrasive the material you grind, the more quickly the wear parts in the interior will wear. To ensure efficient operation and longevity of your Hammer mill, it’s crucial to regularly inspect and maintain its wear parts. These components… Read more »