How are pellet mills transforming agriculture? Dive into the revolutionary tech boosting efficiency, slashing waste, and unlocking groundbreaking solutions.

How are pellet mills transforming agriculture? Dive into the revolutionary tech boosting efficiency, slashing waste, and unlocking groundbreaking solutions.

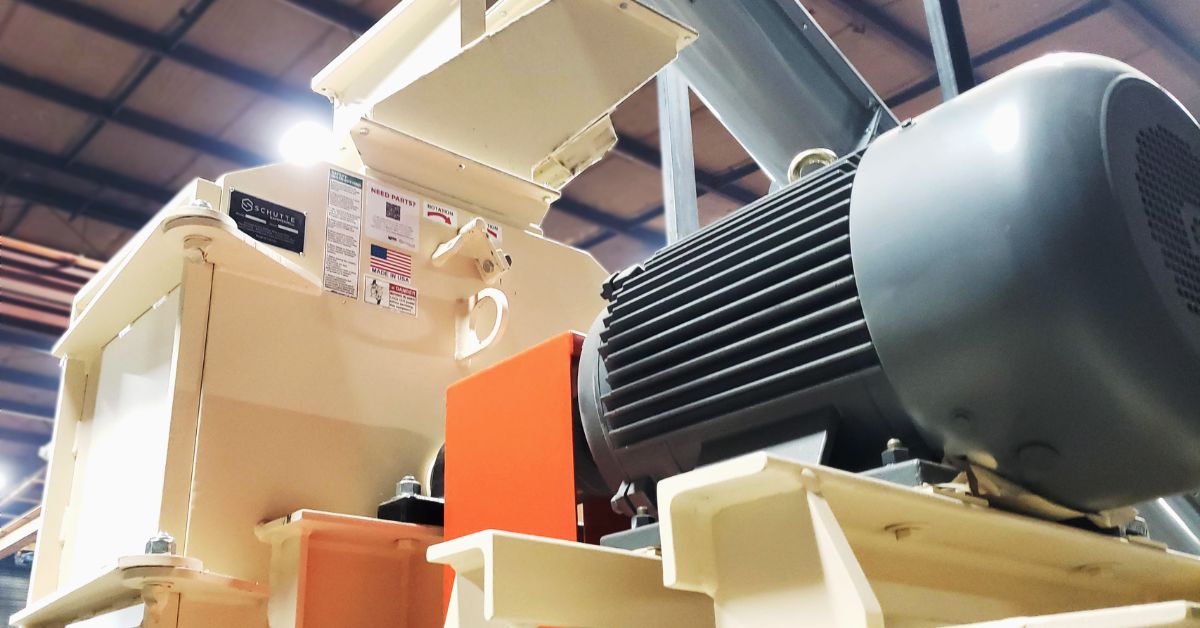

Managing municipal solid waste (MSW) is one of the most pressing challenges of our time. With urbanization and population growth continuing to rise, the need for efficient, sustainable waste management solutions has never been greater. At the forefront of these solutions are hammer mills, versatile machines that play a critical role in the processing and… Read more »

In today’s world, effective wood waste management is more critical than ever. At Schutte Hammermill, we provide innovative size reduction solutions that enable businesses to transform wood waste into valuable resources.

Efficiently manage waste with wood grinders. Learn how these powerful machines transform wood waste into useful materials while reducing environmental impact.

Learn which industries can benefit from high-production hammer mills. Explore their applications, efficiency, and role in optimizing manufacturing processes.